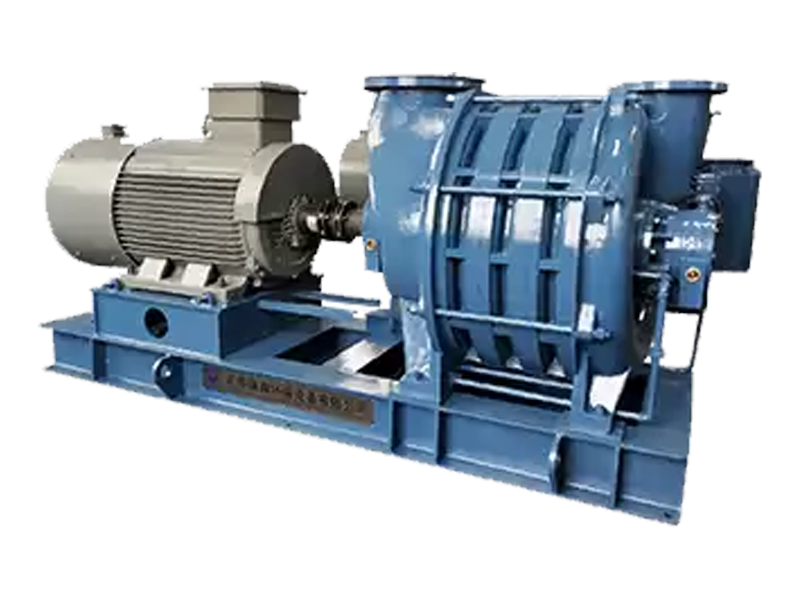

Roots blowers play a pivotal role in industrial applications, facilitating air and gas movement with precision and efficiency. However, not all Roots blowers are engineered alike. In environments where volatile gases, combustible dust, or hazardous materials are present, an explosion-proof Roots blower is indispensable. Understanding the distinctions between a standard Roots blower and its explosion-proof counterpart is essential for selecting the right equipment for critical operations.

1. Structural and Material Enhancements

A standard Roots blower is typically constructed from robust materials such as cast iron or stainless steel, designed to withstand routine operational demands. However, explosion-proof variants take durability a step further. These specialized units incorporate reinforced casings, spark-resistant materials, and anti-static coatings to mitigate ignition risks. Non-sparking alloys such as aluminum-bronze or copper-nickel are frequently used in critical components to prevent friction-induced sparks.

2. Electrical and Motor Protection

A conventional Roots blower employs standard electric motors and wiring, which function efficiently in controlled environments. In contrast, explosion-proof models integrate intrinsically safe electrical systems. These systems feature flameproof enclosures, sealed conduits, and specially rated motors that comply with ATEX, IECEx, or NFPA standards. Such enhancements prevent electrical arcing or heat generation that could ignite flammable atmospheres.

3. Sealing and Containment Measures

Leak prevention is a vital aspect of explosion-proof blowers. While a standard Roots blower may rely on conventional seals and gaskets, an explosion-proof version is equipped with high-integrity sealing mechanisms to contain potential leaks. Double labyrinth seals, gas-tight enclosures, and pressure relief systems ensure that hazardous gases remain confined, reducing the likelihood of ignition sources interacting with the surrounding environment.

4. Operational Safety and Compliance

Explosion-proof Roots blowers undergo rigorous testing and certification processes. Compliance with regulatory frameworks such as OSHA, ATEX (for European markets), and UL (for North America) distinguishes these units from standard blowers. These stringent safety measures are imperative for industries handling volatile substances, including petrochemicals, pharmaceuticals, and wastewater treatment plants.

5. Cost Considerations and Application-Specific Design

Due to their advanced safety features and specialized engineering, explosion-proof Roots blowers generally command a higher price than their standard counterparts. However, this investment is justified in high-risk environments where operational safety is non-negotiable. These blowers are meticulously designed for hazardous zones, ensuring sustained performance under extreme conditions without compromising reliability.

The choice between a standard and an explosion-proof Roots blower hinges on the operating environment and associated safety risks. While standard models suffice for general industrial applications, explosion-proof versions provide unparalleled protection in volatile settings. Understanding these differences enables businesses to make informed decisions, safeguarding personnel, assets, and operational integrity.

русский

русский Español

Español عربى

عربى