In the realm of vacuum technology, two popular pump types are the Roots vacuum pump and the rotary vane pump. Both offer distinct advantages depending on the application, but when it comes to performance, each pump presents unique characteristics that may influence your decision. Understanding the performance distinctions between the two can help optimize your vacuum system for efficiency and longevity.

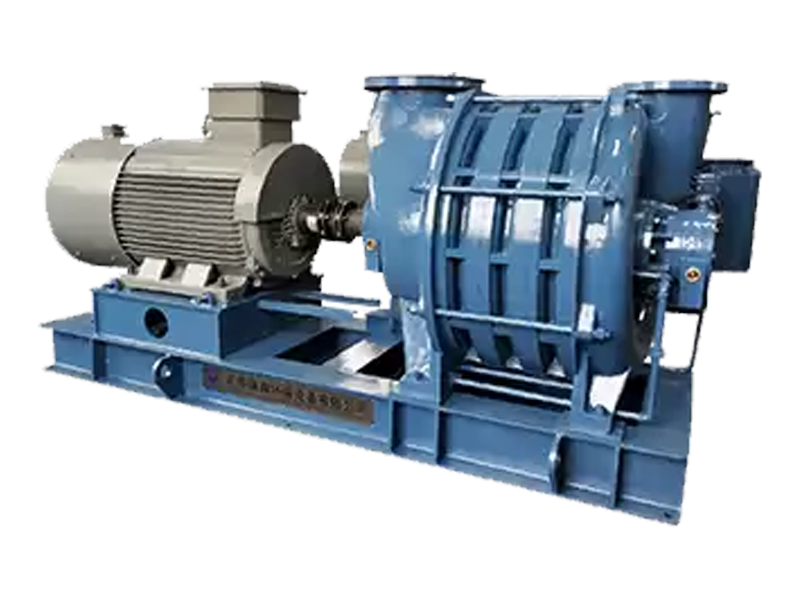

Roots Vacuum Pump: High-Speed Efficiency with Limited Pressure Capability

The Roots vacuum pump operates using a pair of rotors that rotate in opposite directions within a housing, creating a continuous flow of air. This pump is known for its impressive speed and ability to evacuate large volumes of gas. Its efficiency at high speeds is exceptional, allowing it to achieve rapid vacuum creation in systems that require fast evacuation times.

However, the Roots pump is more suitable for low to medium vacuum pressures. While it performs admirably under these conditions, its ability to achieve ultra-high or deep vacuum levels is limited. The nature of its design means it is best used in conjunction with another pump, such as a rotary vane pump or a diffusion pump, to reach higher vacuums.

One of the notable advantages of the Roots pump lies in its low maintenance demands. It has fewer moving parts than other vacuum pumps, which results in less wear and tear over time. This makes it a cost-effective solution in applications where high-speed evacuation is paramount, and the vacuum requirements do not extend to extreme depths.

Rotary Vane Pump: Versatile and Reliable with Superior Low-Pressure Performance

In contrast, the rotary vane pump uses a set of vanes mounted on a rotor that moves within a chamber. As the rotor turns, the vanes slide in and out, creating small chambers that expand and contract, drawing in gas and expelling it as the rotor continues to spin. This mechanism allows the rotary vane pump to achieve a steady and reliable evacuation of gas, making it highly versatile across a wide range of applications.

The rotary vane pump excels at achieving lower vacuum levels compared to the Roots pump. Its performance shines in applications that demand consistent, reliable vacuum levels at pressures ranging from rough to medium vacuum ranges. The rotary vane design allows for better performance under a broader range of operating conditions, including high load scenarios.

While the rotary vane pump may not be as fast as the Roots pump in terms of evacuation speed, it excels in endurance and reliability. It is particularly effective in situations where a consistent and stable vacuum is needed over extended periods. The downside, however, is that the rotary vane pump tends to have higher maintenance requirements, primarily due to the wear and tear on the vanes and the need for regular oil changes to ensure smooth operation.

Key Differences in Performance

Speed and Volume: The Roots vacuum pump is better suited for high-volume gas flow and rapid evacuation, making it ideal for processes that demand quick turnaround times. In contrast, the rotary vane pump provides a steadier, more gradual vacuum creation, ideal for processes that require stable, low-pressure conditions over time.

Vacuum Levels: While the Roots pump is effective at creating low to medium vacuums, the rotary vane pump surpasses it in achieving lower pressures. The rotary vane’s performance at deeper vacuum levels makes it more suitable for applications where deeper vacuum conditions are necessary.

Maintenance: The Roots pump, with its minimal moving parts, requires less maintenance and is more durable in long-term operations. The rotary vane pump, on the other hand, demands more frequent maintenance, particularly with respect to its oil and vanes, which can experience significant wear over time.

Application Suitability: The Roots pump is ideal for systems that require high throughput, such as semiconductor processing or industrial processes, where speed and volume are essential. The rotary vane pump excels in applications requiring consistent low pressure, including laboratory environments, scientific research, and certain industrial processes.

Choosing between a Roots vacuum pump and a rotary vane pump ultimately depends on the specific demands of your application. If your priority is rapid evacuation and handling large gas volumes without a need for extremely deep vacuum pressures, the Roots pump is a highly efficient and cost-effective choice. However, if your application requires deeper vacuum levels and consistent, reliable performance at lower pressures, the rotary vane pump is likely the better option. Understanding these performance differences will ensure you select the most appropriate vacuum pump for your needs, optimizing both performance and longevity in your system.

русский

русский Español

Español عربى

عربى