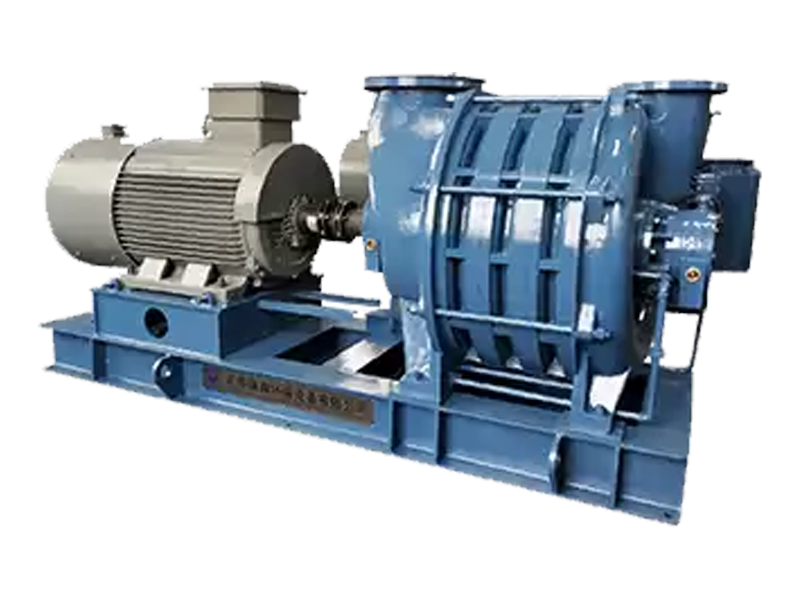

At the heart of every oil-free screw blowers lies a marvel of engineering: the air-end. This component, though often overshadowed by its more prominent counterparts, serves as the nucleus of efficiency and performance. Without it, the entire mechanism would falter, unable to deliver the precision and reliability that industries demand.

The air-end’s primary function is deceptively simple yet profoundly intricate. It compresses air through a meticulously synchronized interplay of rotors. These helical screws, rotating with clockwork precision, trap and propel air forward, creating a continuous flow devoid of contaminants. Unlike traditional systems, the absence of lubricants ensures purity—a non-negotiable requirement for sectors such as pharmaceuticals, food processing, and electronics manufacturing.

Why does this matter? Consider the implications of even the slightest contamination. A single droplet of oil could compromise an entire production line, leading to costly recalls or regulatory penalties. The air-end eliminates this risk entirely, acting as a guardian of quality. Its design operates on principles of thermodynamic elegance, optimizing energy consumption while maintaining output consistency.

Modern advancements have elevated the air-end to new heights. Innovations in materials science have introduced coatings that resist wear and corrosion, extending the lifespan of the component. Meanwhile, computational modeling has refined rotor geometry, enhancing volumetric efficiency and reducing noise levels. The result? A harmonious blend of durability and sophistication.

Moreover, the air-end contributes to sustainability goals. By minimizing energy losses and maximizing airflow, it aligns seamlessly with global efforts to reduce carbon footprints. Industries adopting these technologies not only enhance their operational metrics but also position themselves as stewards of environmental responsibility.

In essence, the air-end is far more than a mechanical part—it is the linchpin of innovation within oil-free screw blowers. Its ability to generate uncontaminated, high-pressure air streams makes it indispensable across diverse applications. From pneumatic conveying to wastewater treatment, its versatility knows no bounds.

To overlook the significance of the air-end is to misunderstand the very foundation of oil-free screw blowers. It embodies the convergence of artistry and science, transforming raw air into a resource of unparalleled value. For those seeking uncompromised performance, the air-end stands as a testament to human ingenuity—a silent yet formidable force driving progress forward.

русский

русский Español

Español عربى

عربى