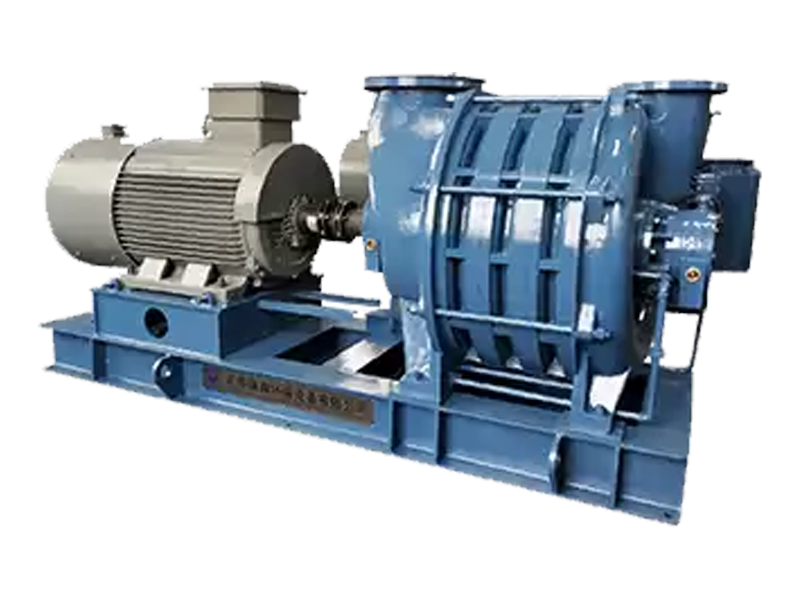

A rotary sliding vane blower is an engineering marvel designed to efficiently generate airflow using a unique combination of rotational mechanics and centrifugal force. Unlike conventional blowers, which rely on impellers or positive displacement mechanisms, this system employs strategically placed vanes within a rotating drum to produce a continuous and controlled stream of air.

Core Mechanism: The Rotary Motion

At the heart of the blower lies a cylindrical rotor, housed within a precision-machined stator chamber. This rotor is eccentrically mounted, meaning it does not rotate along the exact center of the chamber. Instead, it operates at a slight offset, allowing for dynamic movement within the housing. As the rotor spins, centrifugal force compels the sliding vanes—typically made from high-performance composite materials or lubricated graphite—to extend outward, maintaining consistent contact with the stator walls.

Vane Functionality and Air Compression

The vanes divide the stator chamber into multiple dynamic compartments. As the rotor turns, these compartments fluctuate in volume. At the inlet side, a low-pressure zone is created, drawing in ambient air. As the rotor progresses, the vanes sweep the captured air toward the discharge side while progressively reducing the chamber size. This volume reduction results in air compression, generating a pressurized output flow.

Lubrication and Efficiency Considerations

To minimize wear and enhance efficiency, rotary sliding vane blowers typically incorporate an automatic lubrication system. This ensures a thin film of oil coats the stator walls and vanes, reducing friction and extending component longevity. In oil-free models, advanced polymeric vanes are employed to maintain durability while ensuring clean, uncontaminated airflow.

Advantages Over Other Blower Types

Continuous Airflow: Unlike reciprocating compressors, which deliver pulsating output, rotary sliding vane blowers provide a steady and uninterrupted stream of air.

High Efficiency: Their self-adjusting vanes reduce internal leakage, enhancing overall performance.

Compact Design: With fewer moving parts than other blower types, these units are lightweight, space-saving, and relatively simple to maintain.

Versatility: They can be adapted for various applications, including pneumatic conveying, wastewater aeration, and industrial vacuum systems.

The rotary sliding vane blower is a testament to precision engineering, seamlessly combining mechanical ingenuity with practical functionality. By leveraging centrifugal force, dynamic air compression, and efficient vane mechanics, it provides a reliable solution for industries requiring consistent and efficient airflow. Its simplicity, durability, and performance make it a preferred choice across diverse applications, proving that smart design can drive exceptional results.

русский

русский Español

Español عربى

عربى