Water treatment plants are the cornerstone of modern environmental management, ensuring clean, potable water for communities while maintaining the health of aquatic ecosystems. Among the many technologies that drive these facilities, multistage centrifugal blowers are pivotal in maintaining the efficiency and effectiveness of water treatment processes. These robust machines play an essential role in optimizing aeration systems, which are central to various stages of wastewater treatment, including biological treatment, filtration, and chemical dosing.

Aeration Systems: The Heart of Biological Treatment

One of the primary applications of multistage centrifugal blowers in water treatment plants is their contribution to aeration systems. These systems introduce oxygen into wastewater, supporting the microbial communities responsible for breaking down organic contaminants. The blowers deliver the high-pressure airflow necessary to ensure that sufficient oxygen is supplied to the microorganisms, facilitating aerobic digestion—a biological process that removes harmful substances such as nitrogen, phosphorus, and organic matter.

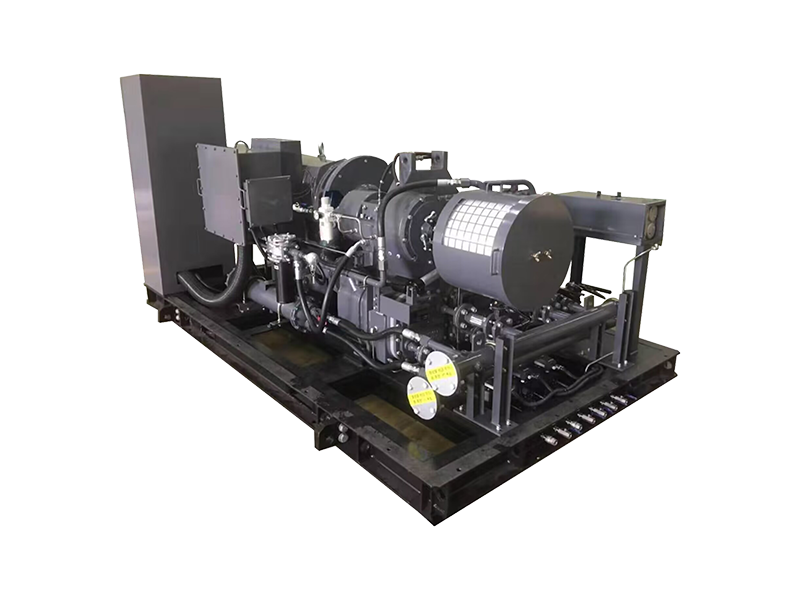

Multistage centrifugal blowers are particularly suited for this role due to their ability to provide steady, high-volume airflow over long periods, a requirement for maintaining consistent oxygen levels in large aeration tanks. Their ability to operate across multiple stages, adjusting airflow based on the needs of the system, offers a high degree of flexibility and control, enhancing the overall treatment process.

Optimizing Energy Efficiency and Cost Reduction

Multistage centrifugal blowers are designed for energy efficiency, which is crucial in a water treatment plant where continuous operation is required. By using a multistage design, these blowers can achieve higher pressure and airflow with lower energy consumption compared to single-stage blowers. This reduction in energy use can lead to significant cost savings over time, making them an economically sustainable choice for plant operators.

Moreover, modern blowers are equipped with variable speed drives (VSDs), allowing them to adjust their performance to the fluctuating demands of the water treatment process. This feature ensures that blowers are not running at full capacity during periods of low demand, further optimizing energy consumption and reducing operational costs.

Enhancing Process Stability and Control

The role of multistage centrifugal blowers extends beyond merely providing oxygen to the wastewater. They contribute significantly to the stability of the entire treatment process. By ensuring that air is distributed evenly throughout the aeration tanks, blowers prevent uneven oxygen levels that could disrupt microbial activity. This consistency is key to achieving optimal treatment efficiency and reducing the risk of treatment failures.

Blowers with advanced controls and sensors can also help plant operators maintain precise aeration control, adjusting airflow dynamically to meet the changing conditions of the water being treated. In turn, this adaptability enhances the plant’s ability to handle variations in influent water quality, whether due to seasonal changes, weather events, or fluctuations in wastewater volume.

Versatility in Filtration and Chemical Processes

In addition to their role in aeration, multistage centrifugal blowers are used in other critical areas of water treatment, such as filtration and chemical dosing. Blowers are responsible for creating the necessary air pressure to push water through sand filters and other filtration systems, ensuring that particulates and contaminants are efficiently removed.

Moreover, in processes such as ozonation and chlorine dosing, multistage blowers support the injection and distribution of disinfectants and chemicals throughout the water. This is especially vital in systems that require precise dosing of ozone or chlorine for disinfection, as the blower’s airflow ensures even distribution and enhanced chemical contact.

Reliability and Longevity in Harsh Environments

Water treatment plants operate in harsh, demanding environments where equipment must endure continuous operation and exposure to corrosive elements. Multistage centrifugal blowers are designed with durability and reliability in mind. Made from high-quality materials such as stainless steel, these blowers are resistant to corrosion and wear, ensuring long service life even under challenging conditions.

Furthermore, their low-maintenance design minimizes downtime, contributing to the overall reliability of the water treatment facility. Regular maintenance schedules and automated monitoring systems can alert operators to any potential issues, ensuring that the blowers continue to operate efficiently and effectively without unexpected failures.

In the intricate world of water treatment, multistage centrifugal blowers are indispensable. From aerating wastewater to optimizing filtration and chemical dosing, these machines ensure that processes run smoothly, efficiently, and cost-effectively. Their ability to deliver high-pressure airflow with minimal energy consumption, coupled with their adaptability and reliability, makes them a critical component in maintaining the high standards required for water treatment plants.

As the demand for clean, safe water continues to grow, the role of multistage centrifugal blowers will only become more vital. By ensuring stable, energy-efficient operations, these blowers contribute not only to environmental sustainability but also to the economic efficiency of water treatment plants worldwide.

русский

русский Español

Español عربى

عربى