In industrial settings, the management of compressed air quality is crucial. An often-overlooked but critical factor is moisture. When air is compressed, its temperature increases, and moisture in the air condenses. Without proper handling, this moisture can lead to a range of problems, from equipment corrosion to inefficiencies in production processes. Oil-free screw blowers, however, are designed with advanced mechanisms to manage and mitigate moisture within the compressed air they produce.

The Role of Oil-Free Screw Blowers in Moisture Control

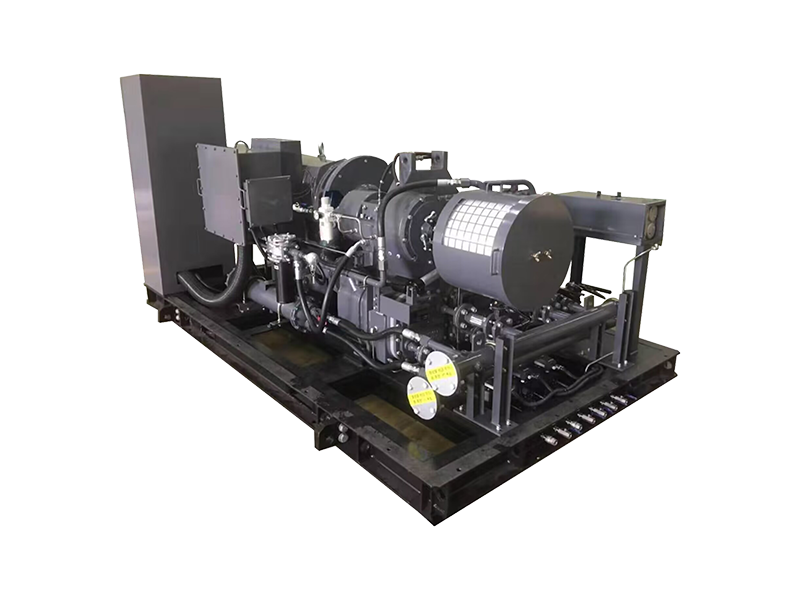

Oil-free screw blowers are engineered to provide high-efficiency air compression without the use of lubricating oil. This is particularly advantageous when moisture is present in the air, as it ensures that the air remains uncontaminated by any oil traces. These blowers operate through a pair of helical screws that compress the air as it passes through the machine, creating a highly efficient and controlled airflow. During this process, moisture in the air is effectively managed to prevent damage to downstream equipment or degradation in product quality.

Condensation and Its Impact

As air is compressed in the screw blower, its volume decreases, and the pressure rises. According to the principles of thermodynamics, this increase in pressure leads to an increase in temperature. However, as the air cools during the expansion phase, the moisture in the air condenses, which can cause severe problems if not addressed. Without the proper systems in place, this condensation can result in water buildup, leading to equipment damage, loss of efficiency, and increased maintenance requirements.

Integrated Moisture Management Systems

To combat the issues of condensation, oil-free screw blowers are often equipped with integrated moisture management systems. These systems include moisture separators, aftercoolers, and dryers that work in tandem to ensure that the compressed air is free from excess water.

Moisture Separators: Positioned at the blower’s output, moisture separators remove large amounts of condensed water from the air. They employ centrifugal force to separate water droplets from the compressed air, effectively preventing water from traveling downstream into critical machinery.

Aftercoolers: Once the air has passed through the blower, it is still at an elevated temperature. An aftercooler helps to lower the temperature of the compressed air, causing additional moisture to condense before it enters the system. This reduces the risk of water buildup and protects downstream components.

Air Dryers: For applications requiring extremely dry air, oil-free screw blowers can be equipped with air dryers that absorb or remove any remaining moisture. These dryers can be desiccant-based or refrigerated, depending on the specific needs of the operation. By drying the air to a set dew point, they ensure that no excess moisture remains in the system.

Why Oil-Free is Better for Moisture Control

Unlike traditional blowers that rely on oil for lubrication, oil-free screw blowers do not introduce any potential for oil contamination into the compressed air. Oil in compressed air systems is a significant factor in the management of moisture. In oil-lubricated systems, moisture can mix with oil, leading to a dangerous combination of water and oil sludge. This not only accelerates wear and tear on the machinery but also compromises the air quality. In contrast, the absence of oil in oil-free screw blowers guarantees that only clean, moisture-controlled air is delivered to the system.

Furthermore, because these blowers do not require lubrication, they reduce the overall risk of oil fouling and its associated issues, ensuring the air remains both dry and uncontaminated. This is especially beneficial in industries such as food processing, pharmaceuticals, and electronics manufacturing, where the quality of the compressed air is paramount to maintaining stringent operational standards.

Oil-free screw blowers are designed to handle moisture in compressed air through sophisticated systems that separate, cool, and dry the air as it moves through the system. By incorporating moisture separators, aftercoolers, and air dryers, these blowers ensure that the compressed air delivered is free from excess water. The absence of oil in these blowers further enhances the efficiency of moisture control, making them the ideal choice for industries that require clean, dry, and reliable compressed air. The result is a system that not only prevents damage to machinery but also boosts operational efficiency and reduces the need for costly maintenance. In essence, oil-free screw blowers offer a superior solution for managing moisture, ensuring long-term reliability and performance in any industrial application.

русский

русский Español

Español عربى

عربى