In the realm of industrial machinery and high-performance engineering, the air suspension turbo blower stands as a pivotal component in optimizing load-bearing capacity. This sophisticated piece of equipment, integral to many applications ranging from heavy-duty vehicles to industrial systems, offers unparalleled benefits in terms of efficiency, stability, and performance.

Understanding the Functionality

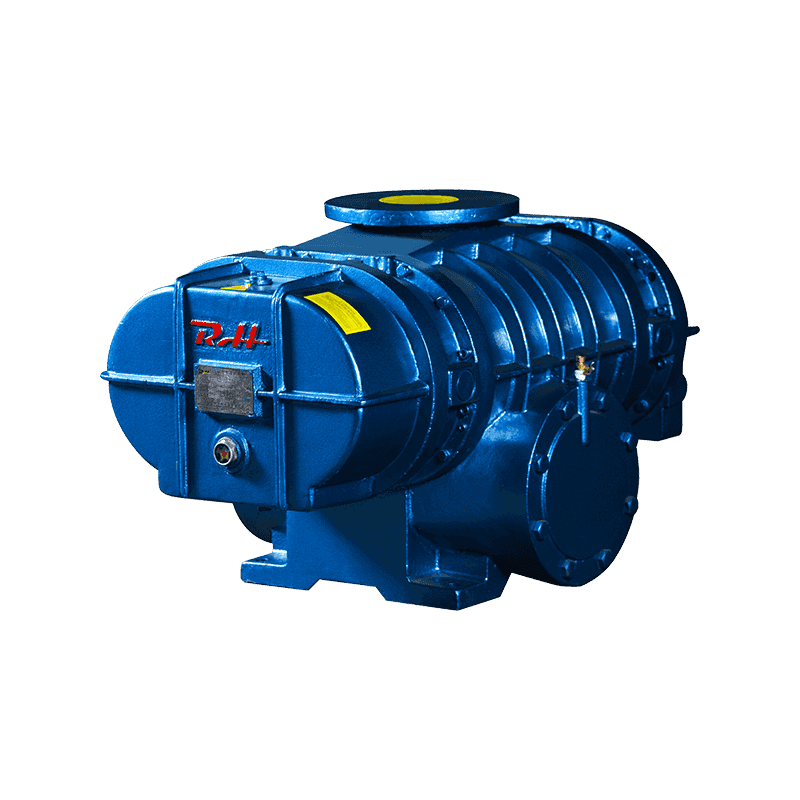

At its core, the air suspension turbo blower is designed to support and enhance the operational efficiency of systems that rely on high air pressure to maintain stability and manage heavy loads. The key feature of this technology lies in its ability to generate a consistent airflow under pressure, which plays a crucial role in facilitating load management. The blower’s operation revolves around a turbocharged mechanism that forces air through the system, creating a cushion effect that reduces friction and mechanical stress on components.

This dynamic airflow system is not just about boosting performance—it’s about ensuring that the system operates with maximum efficiency even under heavy loads. The air suspension feature further amplifies this by allowing for adjustable pressure, which in turn accommodates varying load conditions and prevents system failure.

Boosting Load-Bearing Capacity

One of the primary reasons why air suspension turbo blowers are indispensable in load-bearing applications is their capacity to adapt to fluctuating weights and forces. By adjusting the air pressure within the system, these blowers ensure that the load is distributed evenly, reducing the risk of wear and tear on the machinery. The turbo blower’s air suspension component acts as a shock absorber, mitigating the effects of sudden or uneven weight distribution that could otherwise lead to system malfunction.

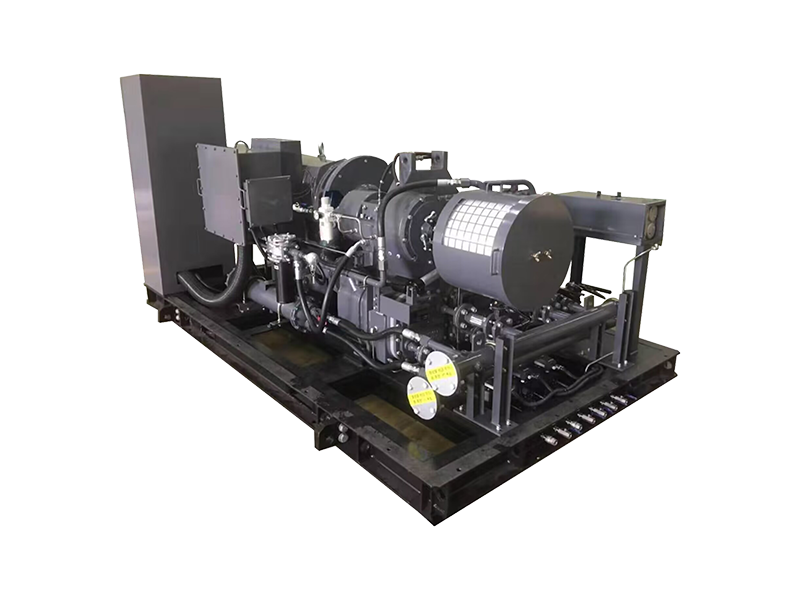

In industrial settings, this ability to dynamically adjust to loads significantly improves the overall stability of the equipment. Whether in transport vehicles or in large-scale manufacturing plants, the blower ensures that machines can handle substantial weight without compromising performance or safety. This makes it particularly vital for industries such as automotive, aerospace, and construction, where load-bearing capacities are frequently pushed to their limits.

Enhancing System Durability and Longevity

Another critical aspect of the air suspension turbo blower’s role in load-bearing capacity is its contribution to system longevity. By ensuring that pressure is evenly distributed, the blower reduces the amount of strain placed on individual components, ultimately extending the life of the system. For instance, in commercial vehicles, this means less wear on the chassis and suspension system, translating to lower maintenance costs and improved operational uptime.

The blower also aids in maintaining the structural integrity of the equipment. Systems that rely on pneumatic pressure are less prone to the mechanical degradation often caused by the frictional forces in traditional load-bearing systems. As a result, air suspension turbo blowers not only enhance performance but also provide long-term cost savings by reducing the need for repairs and replacements.

Efficient Energy Use and Reduced Environmental Impact

While enhancing load-bearing capacity, air suspension turbo blowers also offer significant energy efficiency benefits. Their design focuses on maximizing airflow with minimal energy expenditure, a feature that is crucial in reducing operational costs. This makes them an eco-friendly option for industries seeking to lower their carbon footprint while maintaining optimal performance.

Additionally, the precision with which air suspension turbo blowers manage pressure helps minimize the strain on the power system, resulting in a more energy-efficient operation. This efficiency translates into lower fuel consumption in transport vehicles and reduced energy usage in industrial systems, promoting sustainability without sacrificing performance.

The air suspension turbo blower plays a critical role in enhancing the load-bearing capacity of a wide range of industrial systems. Its ability to maintain consistent airflow under pressure, coupled with its shock-absorbing air suspension, makes it an essential component for ensuring system stability, durability, and performance. By boosting efficiency, reducing wear, and promoting energy savings, the turbo blower is not only a technological asset but also a strategic investment in the longevity and reliability of heavy-duty systems. In industries where load-bearing capacity is paramount, the air suspension turbo blower remains indispensable—enhancing both operational efficacy and overall system resilience.

русский

русский Español

Español عربى

عربى