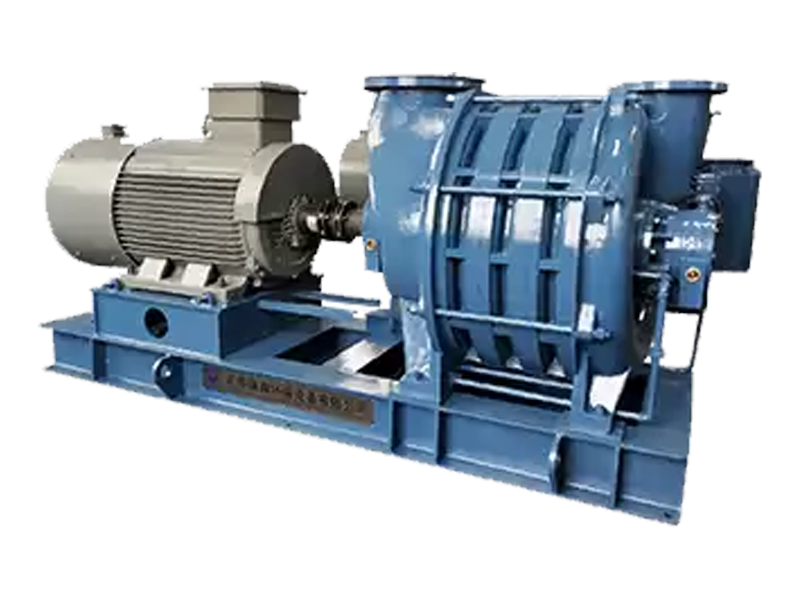

In the realm of modern industrial applications, ensuring the longevity and reliability of critical equipment is paramount. Air suspension turbo blower, renowned for their efficiency and versatility, have emerged as indispensable components across various industries, including water treatment, biopharmaceuticals, and petrochemicals. This article delves into the factors that influence the stability and performance of these advanced machines over extended periods.

The Essence of Precision Engineering

The foundation of an air suspension turbo blower's enduring performance lies in its precision engineering. These machines leverage aerodynamic and mechanical innovations to minimize friction and wear, resulting in reduced energy consumption and prolonged operational life. State-of-the-art designs, such as high-speed direct-drive motors and magnetic bearing systems, eliminate the need for conventional lubrication, thereby mitigating the risk of contamination and mechanical failure.

Routine Maintenance: The Pillar of Longevity

Consistent maintenance protocols are non-negotiable for sustaining peak performance. Periodic inspections, including the assessment of bearing health, rotor alignment, and electronic control systems, can preempt potential issues. Implementing predictive maintenance strategies, supported by IoT-enabled monitoring tools, allows for real-time diagnostics and timely interventions. Such measures ensure that minor inefficiencies do not escalate into costly disruptions.

Environmental Considerations

Ambient conditions play a crucial role in determining the operational efficacy of air suspension turbo blowers. Factors such as temperature, humidity, and particulate matter can influence the performance metrics. Installing advanced filtration systems and environmental controls helps mitigate the adverse effects of these variables. Furthermore, adopting corrosion-resistant materials, such as stainless steel grades SS316 or SS431, fortifies the equipment against harsh environments, thereby enhancing durability.

The Role of Cutting-Edge Materials

The selection of superior materials is a cornerstone of reliability. Stainless steel variants like SS304, SS310, and SS321 offer unparalleled resistance to thermal and chemical stress, making them ideal for diverse industrial applications. By employing high-grade alloys, manufacturers ensure that the components withstand the rigors of prolonged operation without compromising structural integrity.

Customization: Tailoring Solutions to Specific Needs

Customization is pivotal in addressing unique operational challenges. Manufacturers capable of delivering bespoke solutions based on precise specifications, such as size, load capacity, or specialized functionalities, enable industries to optimize their processes. For example, assembly formula sprockets and side bow chains are engineered to adapt to specific turning radii or load requirements, ensuring seamless integration with existing machinery.

Enhancing Energy Efficiency

Energy efficiency is a critical parameter for long-term sustainability. Advanced aerodynamic designs, coupled with optimized control systems, reduce energy consumption without sacrificing output. Incorporating energy recovery mechanisms further amplifies operational efficiency, aligning with global sustainability goals while reducing operational costs.

Collaborative Innovation

Strategic partnerships between manufacturers and research institutions foster continuous advancements. For instance, companies collaborating with academic centers can develop next-generation technologies that address emerging challenges. Establishing R&D cooperation hubs facilitates the rapid prototyping and deployment of innovative solutions, ensuring that air suspension turbo blowers remain at the forefront of industrial innovation.

The enduring stability and performance of air suspension turbo blowers hinge on a confluence of precision engineering, robust maintenance practices, and adaptive innovation. By prioritizing these factors, industries can unlock the full potential of these cutting-edge machines, achieving unparalleled efficiency and reliability. As the demands of modern industrial processes evolve, the role of meticulously designed and maintained equipment becomes ever more critical, underscoring the importance of investing in sustainable and future-ready technologies.

русский

русский Español

Español عربى

عربى