When it comes to industrial ventilation and air movement, multistage centrifugal blowers play a pivotal role in ensuring efficient and effective operations. These workhorses are essential for a wide range of applications, from wastewater treatment plants to power generation facilities.

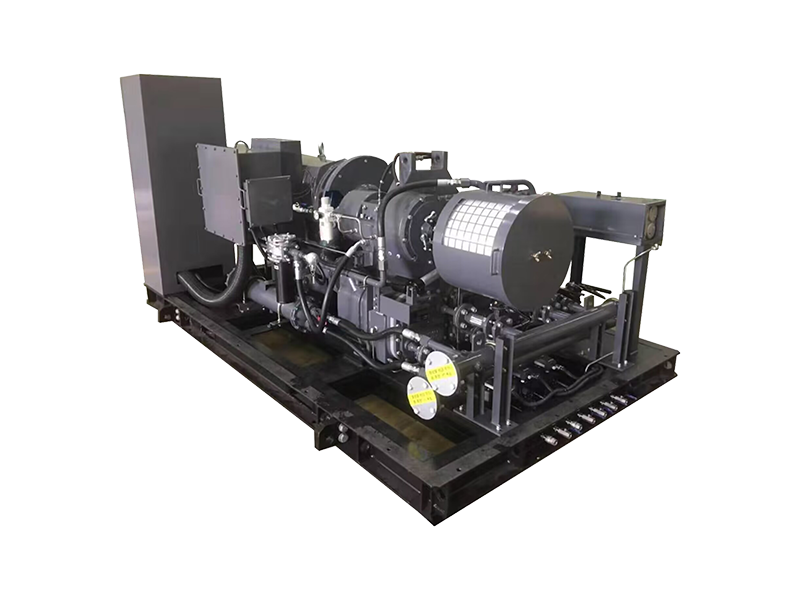

Multistage centrifugal blowers are designed to handle large volumes of air or gas at relatively low pressures. Their unique design, consisting of multiple impellers arranged in series, allows for the gradual compression of air or gas as it passes through each stage. This results in higher overall efficiency compared to single-stage blowers, making them ideal for applications that require a continuous, reliable flow of air or gas. Whether it's pneumatic conveying, wastewater aeration, or combustion air supply, multistage centrifugal blowers excel in delivering the necessary airflow while minimizing energy consumption.

One of the standout features of multistage centrifugal blowers is their ability to operate across a wide range of flow rates and pressures. This flexibility makes them exceptionally versatile, catering to diverse industrial requirements. Additionally, advancements in blower technology have led to the development of high-efficiency models that not only deliver superior performance but also contribute to reduced energy costs and environmental impact. With sustainability becoming a top priority for many industries, the adoption of energy-efficient multistage centrifugal blowers has surged, offering a compelling solution for businesses aiming to optimize their operations while minimizing their carbon footprint.

In the realm of industrial ventilation, reliability is non-negotiable. Multistage centrifugal blowers are engineered to meet this demand, boasting robust construction and minimal maintenance requirements. This reliability translates to uninterrupted operation, allowing industries to uphold stringent air quality standards and operational continuity. Moreover, the integration of smart monitoring and control systems further enhances the performance and longevity of these blowers, enabling proactive maintenance and real-time optimization. As a result, businesses can mitigate downtime and maximize productivity, all while ensuring a safe and compliant working environment for their personnel.

Multistage centrifugal blowers have undoubtedly cemented their status as indispensable assets in the realm of industrial ventilation and air movement. Their ability to deliver high-efficiency airflow, adapt to varying operational demands, and uphold unwavering reliability make them a cornerstone of modern industrial processes. As industries continue to prioritize sustainability and operational excellence, the role of multistage centrifugal blowers will only grow in significance, propelling them to the forefront of innovative and sustainable industrial practices.

русский

русский Español

Español عربى

عربى