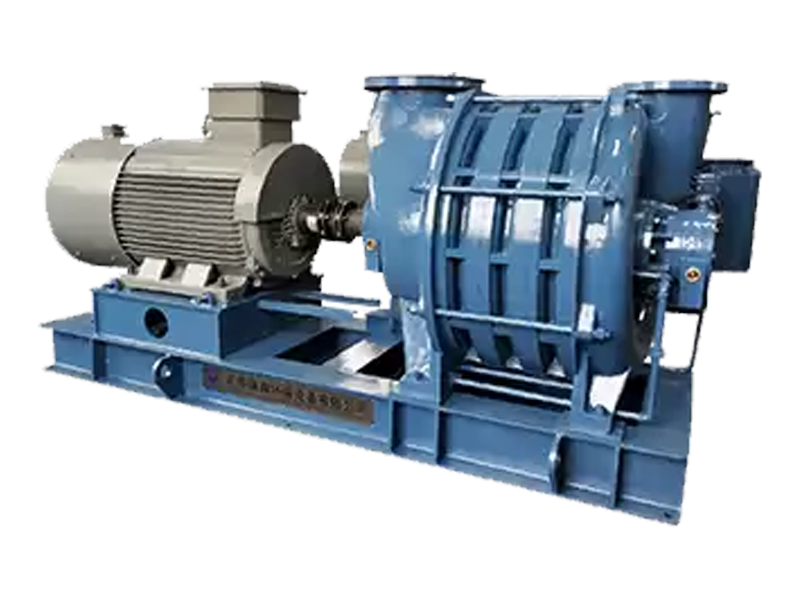

In the world of industrial air and gas handling, centrifugal blowers play a crucial role in various applications, from ventilation systems to pneumatic conveying. Among the different types of centrifugal blowers, the medium flow inlet multi-stage centrifugal blower has gained significant attention due to its unique design and performance capabilities.

A medium flow inlet multi-stage centrifugal blower is designed to handle moderate flow rates while delivering high pressure ratios. This type of blower consists of multiple impellers arranged in series, allowing for a gradual increase in pressure as the gas moves through each stage. The multi-stage design enables the blower to achieve higher pressure ratios compared to single-stage blowers, making it suitable for applications that require elevated discharge pressures.

One of the key advantages of medium flow inlet multi-stage centrifugal blowers is their ability to operate efficiently across a wide range of flow rates. The medium flow inlet allows for optimal performance at moderate flow rates, while the multi-stage design ensures that the blower can maintain high efficiency even at reduced flow rates. This adaptability makes medium flow inlet multi-stage centrifugal blowers a versatile choice for industries with varying process requirements.

Another significant benefit of these blowers is their compact design. By arranging the impellers in series, the overall footprint of the blower is reduced compared to other high-pressure blower configurations. This space-saving feature is particularly advantageous in facilities with limited floor space or where a smaller blower package is desired.

The multi-stage design also contributes to the blower's energy efficiency. As the gas moves through each stage, the pressure rise is distributed evenly, reducing the load on individual impellers. This load distribution minimizes the power consumption required to achieve the desired discharge pressure, resulting in lower operating costs and improved system efficiency.

In terms of maintenance, medium flow inlet multi-stage centrifugal blowers offer several advantages. The modular design allows for easy access to individual stages, simplifying inspection and servicing procedures. Additionally, the robust construction and high-quality materials used in these blowers contribute to their durability and long service life, reducing the frequency of maintenance interventions.

Medium flow inlet multi-stage centrifugal blowers find applications in various industries, including wastewater treatment, chemical processing, food and beverage production, and pharmaceutical manufacturing. Their ability to deliver consistent performance, high pressure ratios, and energy efficiency makes them a preferred choice for processes that demand reliable and cost-effective air and gas handling solutions.

As technology advances, manufacturers of medium flow inlet multi-stage centrifugal blowers continue to innovate and improve their designs. Enhancements in impeller geometry, bearing systems, and sealing technologies have further optimized the performance and reliability of these blowers. Additionally, the integration of advanced control systems and monitoring capabilities has made it easier for operators to optimize blower performance and detect potential issues before they lead to downtime.

Medium flow inlet multi-stage centrifugal blowers offer a compelling solution for industries seeking efficient, high-pressure air and gas handling. Their versatility, compact design, energy efficiency, and low maintenance requirements make them an attractive choice for a wide range of applications. As industrial processes continue to evolve and demand more sophisticated air and gas handling solutions, medium flow inlet multi-stage centrifugal blowers are well-positioned to meet these challenges and contribute to the success of businesses across various sectors.

русский

русский Español

Español عربى

عربى