If you would like to learn more about our products, please feel free to contact us and we will do our to assist you.

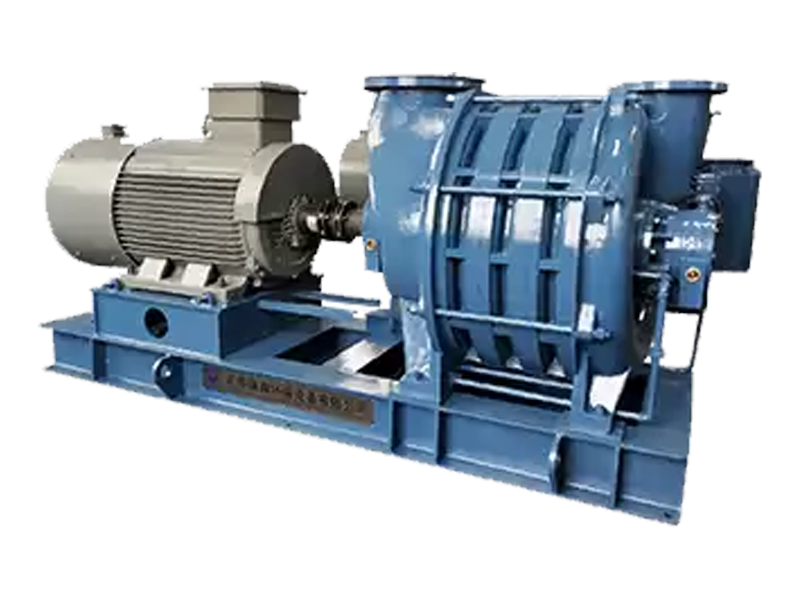

Nantong Rongheng Environmental Protection Equipment Co., Ltd. is a professional company engaged in the development, manufacturing, sales and service of various types of blowers, vacuum pumps and other products. OEM/ODM Rotary blower Manufacturers and Roots Rotary Lobe Blowers Factory in China. Products cover general-purpose three-blade roots blowers, explosion-proof three-blade roots blowers, anti-corrosion three-blade roots blowers, high temperature and high-pressure three-blade roots blowers and units, three-blade roots vacuum pumps and units, rotary fans, Various safety valves, muffler devices, etc. We have a strong R&D team,and we can develop and produce products according to the drawings or samples the customers offered. Provide professional OEM and ODM service to meet your needs. Rotary blower Custom. Having sufficient manufacturing capacity and scale to meet market demand. This includes the number of production equipment, the layout and management capabilities of the production line, as well as the control of the production cycle.

-

1890

Was founded in

-

133+

Industry experience

-

xxx

Patent Certificate

-

xx+

Automatic production line

If you would like to learn more about our products, please feel free to contact us and we will do our to assist you.

-

In the world of industrial machinery, multistage centrifugal blowers are the unsung heroes driving efficiency and perfor...

READ MORE -

With the continuous advancement of industrial technology, air suspension turbo blower, as a high-efficiency and energy-s...

READ MORE -

In industry, efficiency and reliability are crucial. Now, a technology called roots blowers is leading a revolution in i...

READ MORE -

Will the service life of the machine be affected when the rotary blower is operated under high load?

High load operation can potentially affect the lifespan of a rotary blower. Running the blower at high loads for extende...

READ MORE

Rotary blowers are essential components in various industrial and commercial applications, providing the necessary airflow and pressure for processes such as pneumatic conveying, wastewater treatment, aeration, and more. However, choosing the right size and type of rotary blower for a specific application requires careful consideration of several factors to ensure optimal performance, efficiency, and reliability.

Understand Application Requirements:The first step in selecting a rotary blower is to understand the specific requirements of your application. Determine the required airflow in cubic feet per minute (CFM) and the operating pressure in pounds per square inch (PSI). This information can often be calculated based on factors such as equipment specifications, process demands, and air consumption rates. For instance, a pneumatic conveying system may require a certain CFM and PSI to effectively transport materials.

Consider Air Quality Needs:Consider the quality of air required for your application. This includes factors such as cleanliness (free from contaminants), dryness (humidity levels), and temperature. Some applications, like food processing or pharmaceuticals, demand clean and dry air to maintain product integrity and safety. Ensure that the rotary blower you choose can meet these air quality standards.

Evaluate Environmental Conditions:Take into account the environmental conditions where the rotary blower will operate. Consider factors such as ambient temperature, altitude, exposure to corrosive substances, and hazardous environments. Certain blowers are designed to withstand harsh conditions better than others, so selecting a blower that can operate reliably in your specific environment is crucial for long-term performance.

Choose the Right Type of Rotary Blower:There are different types of rotary blowers available, each suited for specific applications:

Positive Displacement Blowers: These include rotary vane blowers and rotary screw blowers, ideal for applications requiring constant airflow and moderate pressures.

Centrifugal Blowers: Suitable for applications needing high airflow rates and lower pressure ratios.

Regenerative Blowers: Effective for applications with moderate airflow rates and higher pressure differentials.

Consider the characteristics and performance capabilities of each type to determine which one aligns best with your application requirements.

Calculate Power Requirements:Determine the power source available (electric, diesel, etc.) and calculate the power requirements in horsepower (HP) based on the airflow, pressure, and efficiency of the selected rotary blower. Ensure that the power source can provide sufficient power to operate the blower effectively.

Consider Space and Installation Requirements:Evaluate the available space for installing the rotary blower and consider factors such as noise levels, vibration, and any special installation requirements (such as mounting options, ventilation, etc.). Ensure that the chosen blower can be installed and operated efficiently in your facility.

русский

русский Español

Español عربى

عربى